About

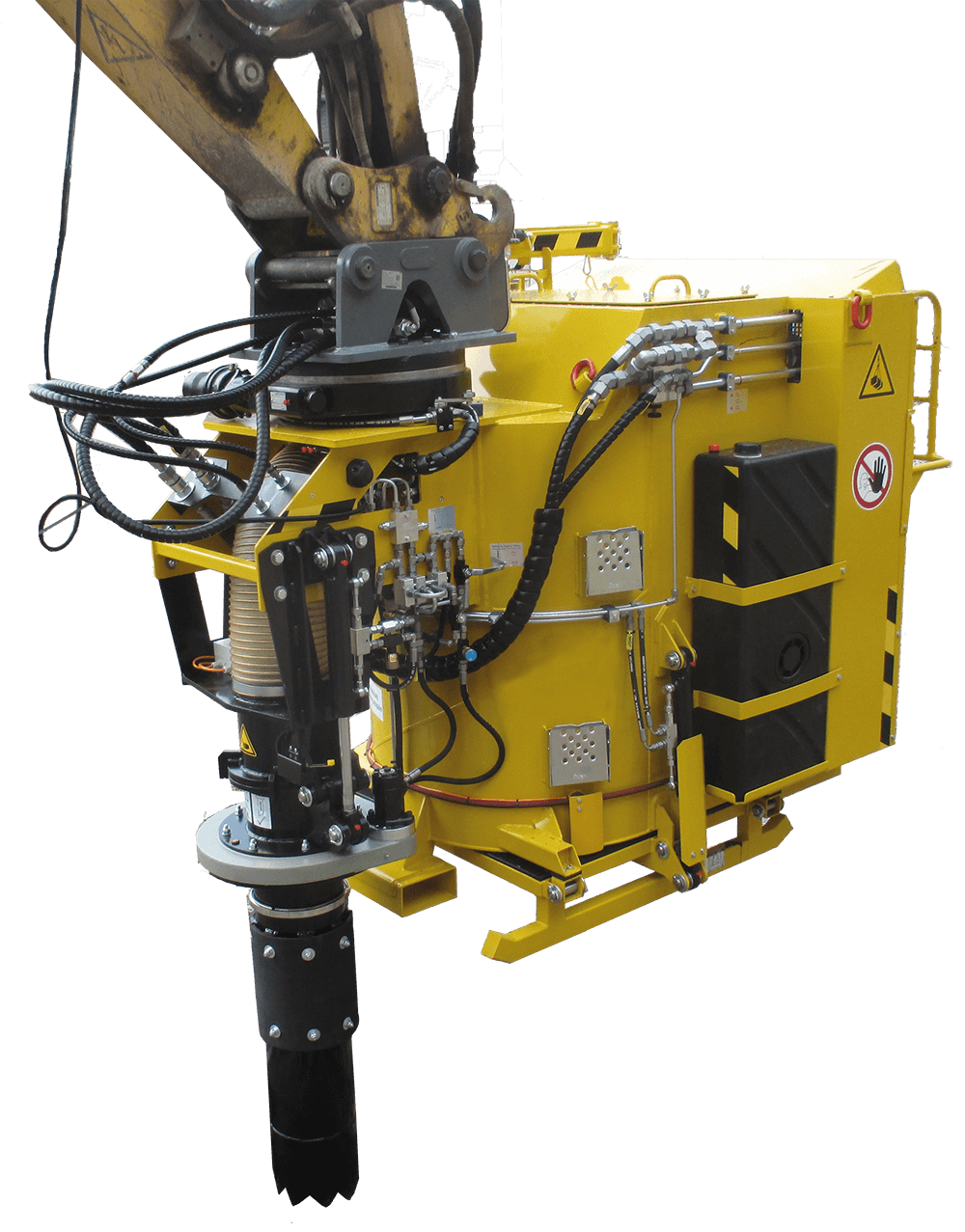

The tinbin TC2 is a hydraulically driven, pneumatically functioning suction device that attaches to your excavator The TC2 has the ability to suck mineral building materials, ground and gravel etc. via a concentrated vacuum and is perfect for a variety of jobs in rail construction, landscaping, municipal work and excavation.

The radial ventilator generates a strong air flow, with which the material is carried into the container chamber from here the material can be dumped on site or into a bin. The TC2 model brings new innovations like dust suppression and a cylindrical container to improve dumping! One amazing benefit of the TC2 is that it's an uncomplicated and economical alternative to manual labor.